Technical Data

DC Motor

Motor Capacity

Key Features

DC motor has excellent mobility since it has a large starting torque. It also has a large output and high efficiency compared to an AC motor of the same size. Compared to the AC motor, various voltage specifications can be applied. In particular, the low voltage motor specifications applicable to the portable type set of the battery power (12 V, 24 V, etc.) are supported.

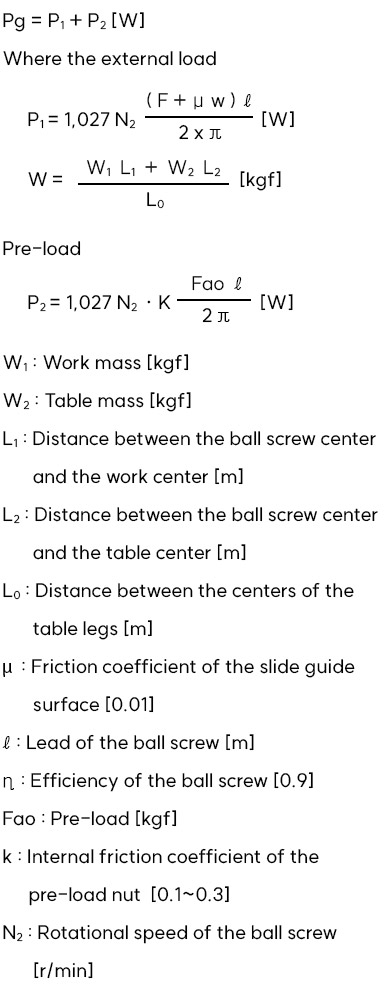

DC Motor characteristic curve

Selection Conditions

Generally, the capacity of the DC motor is indicated by output, and motor capacity refers to the output specifications at the maximum efficiency point (load). The motor is not affected even when heat is generated by current and temperature becomes saturated when used at this maximum efficiency point, and it is usable even in continuous operation.

Sometimes it is used at the maximum output (pop) point or at more than 80% of the torque point, where the motor is locked. However, it can be used for instantaneous operations only, in that case. If the motor is used under overload conditions as described above, durability may be affected.

Sometimes it is used at the maximum output (pop) point or at more than 80% of the torque point, where the motor is locked. However, it can be used for instantaneous operations only, in that case. If the motor is used under overload conditions as described above, durability may be affected.

comparison

Advantages

- Easy to control speed, easy forward/reverse rotation, and instantaneous stop.

- Large starting torque.

- Greater output and higher efficiency compared to AC motors with the same output.

- Low-voltage specifications and simplified insulation compared to AC motors.

Disadvantages

- Limited lifespan brush.

- Noise generated by brush and commutator.

The required capacity of the motor can be calculated as follows:

The basic formula for the general state is described here.

Therefore, when a motor is actually selected, various factors should be considered,

such as acceleration during starting, power required for a large instantaneous load,

safety during design and manufacturing, and the effects of voltage fluctuations.

The basic formula for the general state is described here.

Therefore, when a motor is actually selected, various factors should be considered,

such as acceleration during starting, power required for a large instantaneous load,

safety during design and manufacturing, and the effects of voltage fluctuations.

When hoisting a load

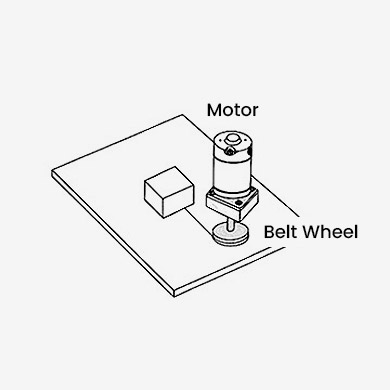

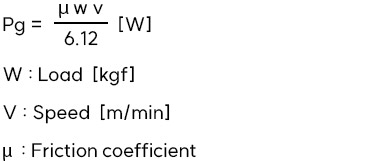

When moving the contact surface horizontally

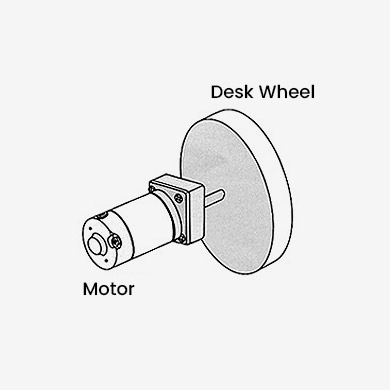

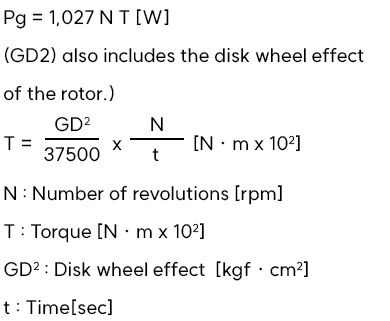

When driving an inertial body

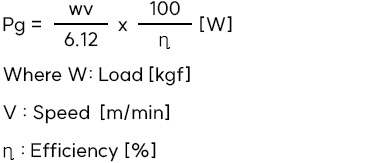

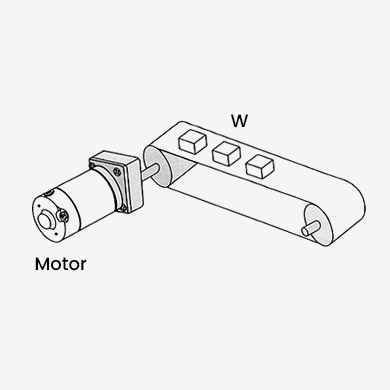

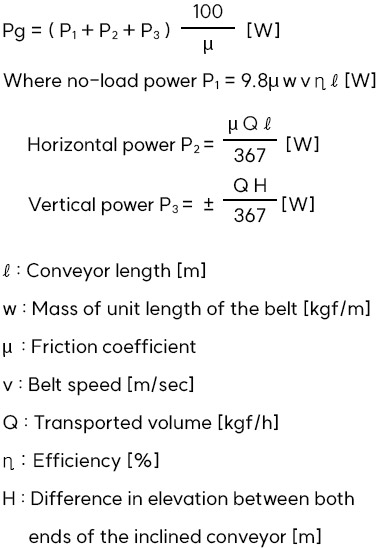

Belt conveyer

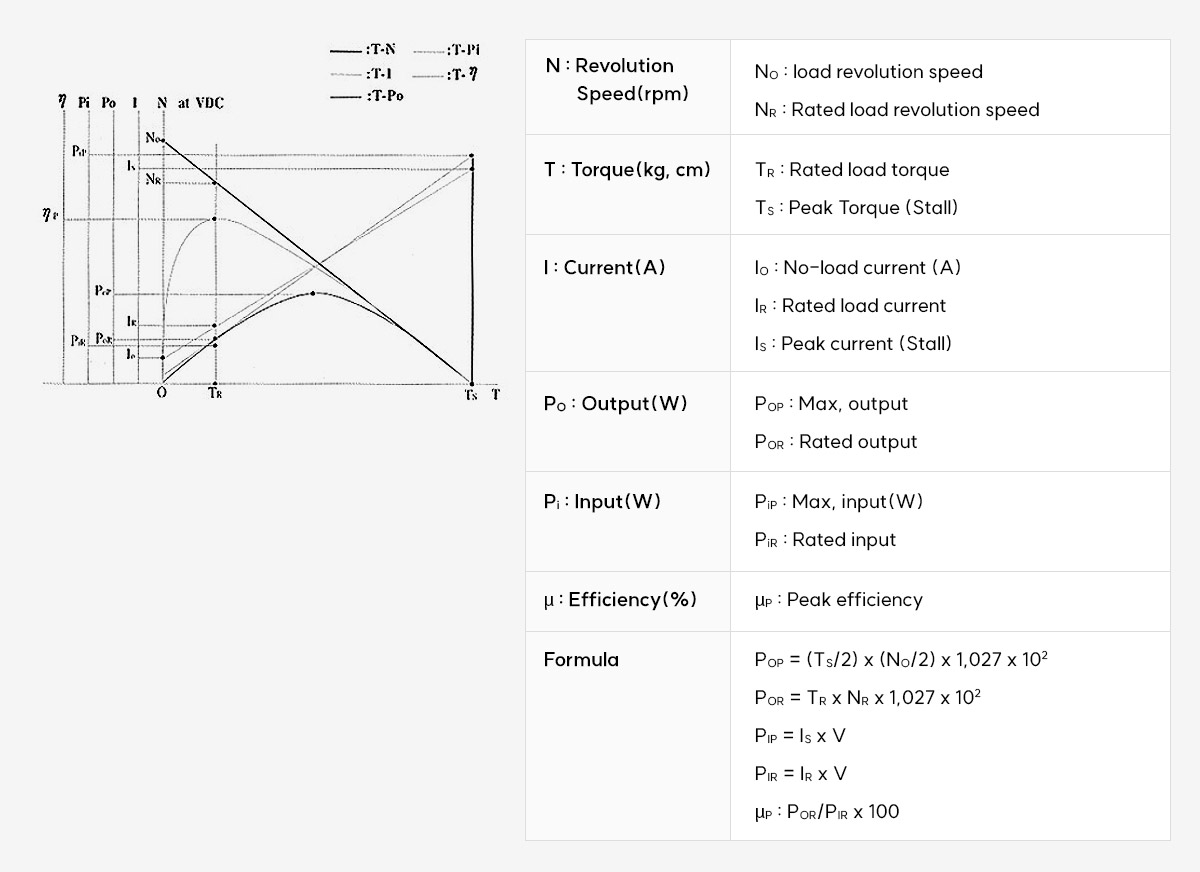

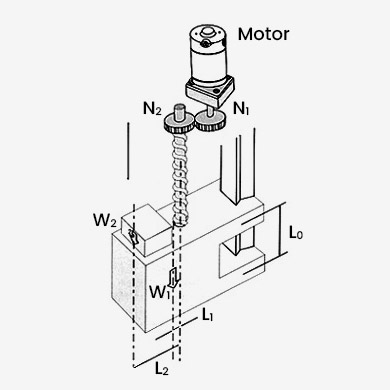

When driving a ball screw